The EU Pressure Equipment Directive has been updated from 97/23/EC to 2014/68/EU, and the new directive will be enforced from July 19, 2016. The 'Pressure Equipment Directive' (hereinafter referred to as the PED Directive) is one of the many EU directives targeting pressure equipment, which stipulates the basic safety requirements (ESRs) for pressure equipment and maintains the current safety level of pressure equipment in the EU. It is suitable for the design, manufacturing, and qualification evaluation of pressure equipment and complete equipment with a maximum working pressure greater than 0.5 bar.

The specific content update date is as follows:

Released on June 27, 2014;

July 17, 2014~February 28, 2015: Article 13 Transition Period;

From February 28, 2015 to June 1, 2015: Article 9 of the old directive and Article 13 of the new directive can be used simultaneously;

On June 1, 2015, Article 9 of the old directive was abolished and Article 13 of the new directive was used;

2016/7/19: Cancel 97/23/EC and implement 2014/68/EC.

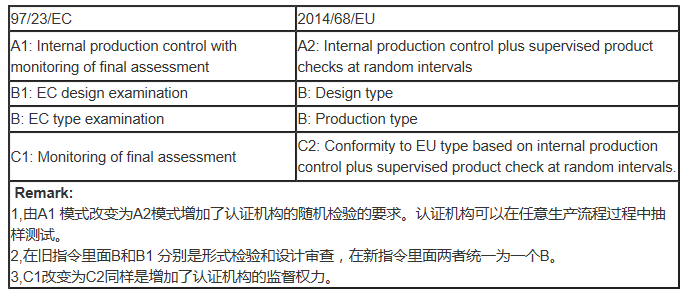

Authentication mode change:

Risk level classification of PED instructions

According to Appendix II of PED, pressure equipment can be classified into four qualification evaluation levels: I, II, III, and IV. Pressure equipment with low risk can be operated according to mature engineering practice SEP (Sound Engineering Practice).

To achieve the classification of pressure equipment, manufacturers need to understand the following knowledge.

1) Equipment type: pressure vessels, pipelines, pressure accessories, safety accessories

2) Fluid state: gas or liquid. At the highest operating temperature of the equipment, if the saturated vapor pressure (gauge pressure) of the fluid does not exceed 0.5 bar, it is considered a liquid, otherwise it should be considered a gas.

3) Fluid group

Group 1- Hazardous fluids: explosive, highly flammable, highly flammable, flammable (maximum allowable temperature exceeding flash point), highly toxic, toxic, and oxidizing

Group 2- Non hazardous fluids: fluids other than Group 1

4) Maximum allowable pressure PS and volume V/nominal size DN of equipment

5) Maximum operating temperature TS of the equipment

Based on the above information and referring to the 'Risk Level Classification Basis', manufacturers can determine the relevant classification chart in Appendix II of PED. Then, in the selected classification chart, coordinate points are marked based on the maximum allowable pressure PS and volume V/nominal size DN of the equipment to determine the category of pressure equipment.

Pressure bearing accessories can be classified as either pressure vessels or pressure pipelines, whichever is relevant. When both volume and nominal size are considered relevant, the category of pressure bearing accessories should be the highest among them.

Safety accessories are generally classified as Class IV, but as a special category, some special equipment safety accessories can be classified into the same category as the equipment they protect.