Test Method for Minimum Tightening Torque of Spinning Caps

In the AST M standard catalog, the test standard for the minimum tightening torque of pressure spinning covers is AST M D 3810-1997 (2002) 'Test Method for Minimum Application Torque of Type IA Child Resilient Closures'. The main purpose of this test method is to determine the minimum tightening torque value to verify the usage time of the child protection characteristics of the pressure spinning cover. The minimum tightening torque value will affect the fully degraded opening torque value, and during use, the degraded opening torque must be greater than the expected maximum reverse ratchet torque. The test method of minimum tightening torque can be used to compare the protective characteristics of two or more types of screwing caps for children, as well as to analyze the effects of factors such as lining materials, bottle cap materials, and container types on the protective characteristics of children.

The test sample is a pressure spun child safety cover that has been pre processed under certain environmental conditions. Detect the minimum torque values of five samples at each time interval and at each torque level as data points. The selected data points must ensure that there is no significant change in torque degradation during the shortest duration of four weeks. For example, on the third day of the experiment, there was a significant change in torque, but there is still a possibility of torque change in the remaining time. The time points for detecting data can be selected as Day 1, Week 1, Week 2, Week 3, and Week 4.

The time, temperature, and humidity conditions of the test have a significant impact on torque detection. To ensure the repeatability of the test, specific test conditions must be determined. Table 1 shows some special environmental conditions that can be selected. Before conducting a lid container system inspection, each component must be placed independently under specific environmental conditions for at least 48 hours, and should not be stacked to ensure sufficient circulation in the surrounding environment.

Detection steps

① Firstly, determine the tightening torque of three levels, and select the smallest level for testing. The following are some recommended opening torque ranges for different tests: 0.90 N · m -. 13 N · m; 1.58 N · m-1.31 N · m; 2.15 N · m-2.37 N · m; 2.71 N · m -2.94 N · m.

② Simulate the process environmental conditions of container cleaning, hot filling, and capping, and place the cap container system under the simulated environmental conditions for testing. The torque detection test must be completed within 2 hours after environmental pretreatment. The detection of tightening torque and opening torque must be completed by one operator to reduce operational errors.

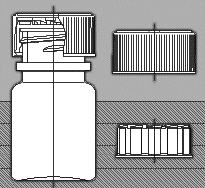

③ Using a platform type torque tester, tighten all the screw caps smoothly and slowly at the same speed.

④ Tighten five bottle caps with the minimum tightening torque in each level, and then immediately use a platform type torque detector to smoothly and slowly open the spinning cap at the same speed, recording the opening torque value.

⑤ Under storage environment conditions, increase the tightening torque levels in sequence and tighten five bottle caps with the average tightening torque of each level. Then open the pressure spinning cover, as shown in ④. ⑥ When there is no significant change in the opening torque, record the level of tightening torque or opening torque at this time. The measured fully degraded opening torque of a certain level must be greater than the expected maximum reverse ratchet torque.

note

In the inspection report, it is necessary to clearly describe the threaded structure, inner and outer cover materials, inner cover coating materials, container materials, and structural factors of the pressure spinning cover. When the minimum tightening level corresponding to the minimum opening torque level is determined, the control level of torque on the packaging production line can be determined.

Contact number: 4006 288 2110755 27454498