ASTM D 3475-1995(2003)

(Classification of Child-Resistant Packages)

The United States was the earliest country to conduct research on child safety packaging and develop testing methods and standards, and its standards and regulations for child safety packaging are relatively rich and complete. In the American Society for Testing and Materials (AST M) standard catalog, there are a total of 9 standards related to child safety packaging, which provide specific requirements for some child safety packaging rules, mainly focusing on the classification methods of child safety packaging and the opening and testing methods of child safety packaging.

Among them, ASTM D 3475-1995 (2003) 'Classification of Child Resilient Packages' classifies children's safety packaging products. The compression type child safety cover is a common packaging form in the market for child safety packaging. In the ASTM D 3475-1995 standard, this packaging cover belongs to the IA type child safety cover.

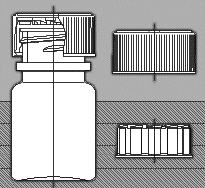

The pressure spinning type child safety cover is generally a two piece laminated cover with an inner core made of polypropylene injection molding and an outer cover made of polyethylene injection molding. The structural diagram is shown in Figure 1. When opening, the outer and inner covers must be tightly pressed, so that the tongue inside the outer cover presses against the protrusion at the end of the inner cover, and the teeth fit together while rotating. Otherwise, there will be only a clicking sound that cannot be opened. When tightening this cap, only fit the bottle mouth as usual and tighten it. Due to the different opening method of this cap from ordinary bottle caps, it can prevent children from opening and accidentally taking it, and has a safety protection effect on the use of drugs. At present, some companies in the market are promoting the use of pressure spinning caps in the packaging of more products, as shown in Figure 2, from pharmaceutical packaging to the packaging of household chemicals such as bleach, and from tablet packaging to liquid packaging.

Relevant testing standards

GB/T 17876、BB/T 0025、BB/T 0034(GB/T 14803)、 ASTM D 2063、ASTM D 3198、ASTM D 3474、YBB00052005-2015、YBB00092002-2015、YBB00392003-2015、YBB00112002-2015

Contact number: 4006-288-211,0755-27454498